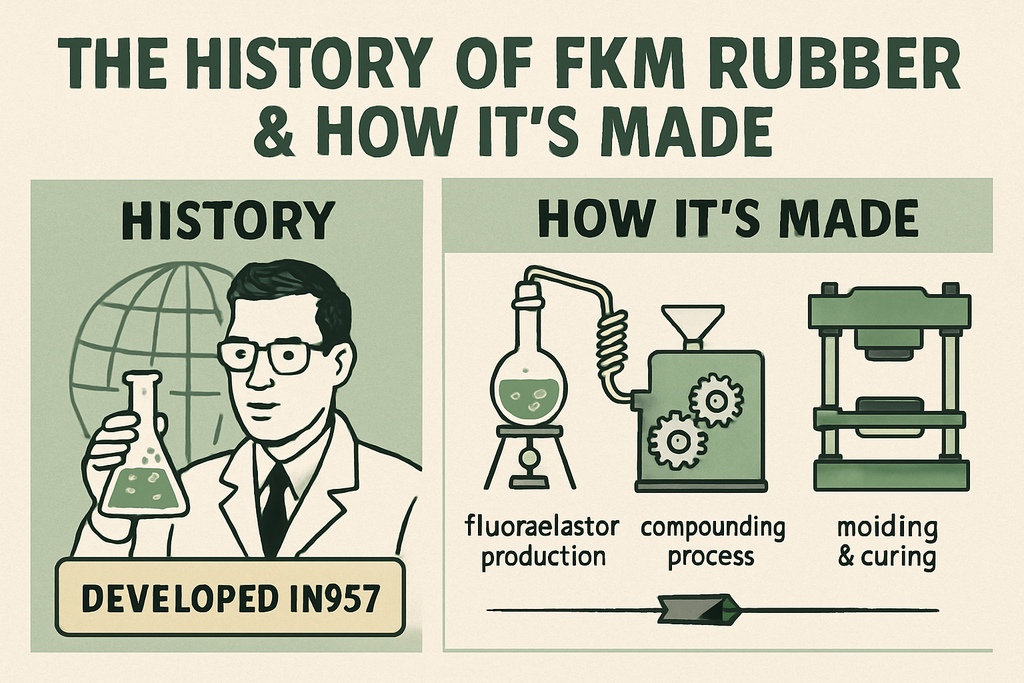

The history of FKM rubber & how its made.

- Origins of Fluoroelastomer Technology

- The Birth of Viton®

- Chemical Composition and Molecular Structure

- Crosslinking Chemistry

- The Premium FKM Watch Strap Solution

- Why FKM Excels for Timepieces

- Manufacturing Process of FKM Rubber

- Compounding and Vulcanization

- Evolution in Horological Applications

- Modern Manufacturing Refinements

- Performance Characteristics

- Comparative Advantages

- Future Developments and Applications

Origins of Fluoroelastomer Technology

The genesis of FKM rubber traces back to the demanding requirements of post-World War II industrial applications. During the 1950s, engineers grappled with creating materials capable of withstanding extreme temperatures, corrosive chemicals, and harsh environmental conditions that traditional elastomers simply could not endure.

DuPont's pioneering research into fluoropolymer chemistry led to the development of fluoroelastomer compounds in 1957. These synthetic rubbers represented a revolutionary leap in material science, combining the flexibility of conventional rubber with unprecedented chemical inertness and thermal stability.

The Birth of Viton®

DuPont's Viton® brand became synonymous with high-performance fluoroelastomers. The trademarked material emerged from extensive research into vinylidene fluoride copolymers, establishing the foundation for modern FKM formulations.

Initially designed for aerospace applications, Viton® demonstrated exceptional resistance to jet fuels, hydraulic fluids, and extreme temperature fluctuations. This durability made it indispensable for critical sealing applications in military and commercial aviation.

Chemical Composition and Molecular Structure

FKM rubber's exceptional properties stem from its unique molecular architecture. The polymer backbone consists of carbon-fluorine bonds, which are among the strongest chemical bonds in organic chemistry.

The fluorine atoms create a protective sheath around the carbon chain, providing unparalleled resistance to chemical attack and thermal degradation.

Various FKM formulations exist, categorized by their monomer composition:

- Type A: Vinylidene fluoride and hexafluoropropylene copolymers

- Type B: Vinylidene fluoride, hexafluoropropylene, and tetrafluoroethylene terpolymers

- Type F: Vinylidene fluoride and perfluoromethyl vinyl ether copolymers

Crosslinking Chemistry

The vulcanization process transforms linear FKM polymers into three-dimensional networks through various crosslinking mechanisms. Bisphenol curing systems remain the most common, utilizing phenolic curatives to create stable C-C bonds between polymer chains.

The Premium FKM Watch Strap Solution

Modern horological enthusiasts increasingly recognize FKM's superiority for watch strap applications. The material's inherent properties address common issues plaguing traditional watch bands: degradation from sweat, discoloration from UV exposure, and brittleness from temperature extremes.

Strapmeister's FKM Textured Rubber Strap exemplifies this premium approach to watch band engineering. Crafted from authentic fluoroelastomer compounds, this strap delivers the durability and comfort that luxury timepiece owners demand. The textured surface provides enhanced grip while maintaining the material's characteristic smoothness against the skin.

Why FKM Excels for Timepieces

The hypoallergenic nature of fluoroelastomers makes them ideal for prolonged skin contact. Unlike conventional rubber compounds, FKM resists accumulating dust, lint, or oils, maintaining its pristine appearance throughout extended wear cycles.

Manufacturing Process of FKM Rubber

The production of FKM involves sophisticated polymerization techniques requiring precise control of reaction parameters. Emulsion polymerization remains the predominant method, utilizing aqueous dispersions of fluorinated monomers.

| Process Stage | Temperature Range | Duration |

|---|---|---|

| Monomer preparation | -20°C to 0°C | 2-4 hours |

| Polymerization | 80°C to 120°C | 6-12 hours |

| Coagulation | 60°C to 80°C | 1-2 hours |

Compounding and Vulcanization

Raw FKM polymers undergo compounding with various additives including fillers, processing aids, and curing agents. This stage determines the final properties of the elastomer, allowing manufacturers to tailor characteristics for specific applications.

The vulcanization process typically occurs at temperatures between 150°C and 200°C. Post-cure heat treatment at elevated temperatures removes volatile compounds and optimizes the crosslink network.

Evolution in Horological Applications

The transition from industrial to consumer applications marked a significant milestone in FKM's history. Watch manufacturers initially adopted fluoroelastomers for professional diving watches, recognizing their superior resistance to saltwater and pressure variations.

Luxury brands began incorporating FKM straps in the 1980s, particularly for sports watches designed for extreme environments. The material's ability to maintain elasticity across temperature ranges from -40°C to +200°C proved invaluable for aviation and diving timepieces.

Modern Manufacturing Refinements

Contemporary FKM production incorporates advanced purification techniques to eliminate trace contaminants that could affect biocompatibility. Specialized grades developed for skin-contact applications undergo rigorous testing to ensure dermatological safety.

Surface treatments and texturing techniques enhance both aesthetic appeal and functional performance. Laser etching, embossing, and chemical etching create distinctive patterns while maintaining the material's inherent properties.

Performance Characteristics

FKM's exceptional service life stems from its resistance to multiple degradation mechanisms. Ozone resistance prevents cracking under atmospheric exposure, while chemical inertness protects against common solvents and cleaning agents.

The low compression set values ensure that FKM straps maintain their original dimensions and fit throughout their service life. This dimensional stability proves particularly important for precision timepiece applications where consistent tension and comfort are paramount.

Comparative Advantages

When compared to natural rubber, silicone, or conventional synthetic elastomers, FKM demonstrates superior performance across multiple criteria. Its tensile strength typically ranges from 10 to 20 MPa, with elongation values exceeding 200%.

The material's low permeability to gases and moisture provides additional benefits for watch strap applications, preventing the absorption of odors or liquids that could compromise hygiene or appearance.

Future Developments and Applications

Ongoing research in fluoroelastomer technology focuses on enhancing sustainability while maintaining performance. Bio-based feedstocks and improved recycling methods represent emerging areas of development.

Advanced FKM formulations incorporating nanomaterials promise enhanced mechanical properties and novel functionalities. These developments may introduce antimicrobial properties or improved UV resistance for next-generation watch strap applications.

For discerning watch enthusiasts seeking the ultimate combination of durability, comfort, and aesthetic appeal, FKM straps represent the pinnacle of elastomeric engineering. The material's proven heritage in demanding aerospace and automotive applications translates seamlessly to horological excellence, ensuring that luxury timepieces receive the premium straps they deserve.

Comments on this post (0)